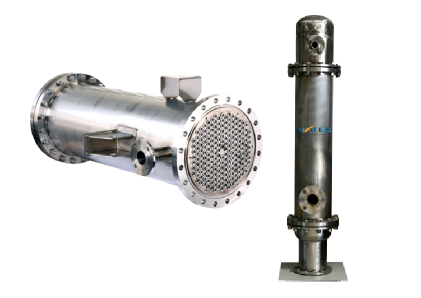

Condensor

Revolutionizing Heat Exchange: NXTEK is a Shell and Tube Condensers Provider in India

Leading the Industry as a Premier Shell and Tube Condenser Provider and Manufacturer

Efficient Customizable Shell and Tube Condensers

Innovative Shell and Tube Design

At the core of NXTEK Yantra's offerings is its innovative Shell and Tube Condenser design. This configuration is engineered for maximum heat exchange efficiency, making it a cornerstone in various industrial applications.

Versatility for Multiple Industries

NXTEK Yantra's Shell and Tube Condensers cater to a wide range of industries, from petrochemicals and HVAC to power generation. This versatility positions these condensers as indispensable components in diverse industrial processes.

Efficient Heat Transfer

The primary function of a condenser is efficient heat transfer, and NXTEK Yantra's design excels in this regard. The Shell and Tube configuration enhances surface area contact, facilitating optimal heat exchange for increased efficiency.

Customization for Specific Requirements

Recognizing the unique needs of clients, NXTEK Yantra offers customization options for its Shell and Tube Condensers. Whether it's size variations, material preferences, or specific features, these condensers can be tailored to suit the exact requirements of each application.

Materials for Durability and Longevity

The construction of NXTEK Yantra's condensers prioritizes materials that ensure durability and longevity. This commitment not only extends the operational life of the condensers but also enhances their reliability in demanding industrial environments.

Energy Efficiency for Sustainable Operations

As sustainability gains prominence, NXTEK Yantra's Shell and Tube Condensers are designed with energy efficiency in mind. These condensers contribute to reduced energy consumption, aligning with the global push for environmentally responsible industrial practices.

Compact Design for Space Optimization

The compact design of the Shell and Tube Condensers allows for efficient space utilization in industrial settings. This feature is particularly valuable in applications where space constraints are a consideration, providing flexibility in installation.

Ease of Maintenance and Cleaning

Maintenance is streamlined with the design of NXTEK Yantra's condensers. The accessibility of components facilitates ease of cleaning and maintenance, reducing downtime and ensuring consistent performance over the operational life.

Applications in Petrochemical Processes

The petrochemical industry relies heavily on efficient heat exchange, and NXTEK Yantra's Shell and Tube Condensers play a crucial role in processes such as distillation and chemical production. These condensers contribute to the overall efficiency and productivity of petrochemical operations.

Global Recognition and Client Satisfaction

With a global presence, NXTEK Yantra has gained recognition for its Shell and Tube Condensers. Positive feedback from satisfied clients underscores the reliability, adaptability, and performance of these condensers across various industries.

Continuous Research and Development

NXTEK Yantra remains at the forefront of research and development in heat exchange technology. The company is dedicated to staying abreast of industry advancements, ensuring that its Shell and Tube Condensers evolve to meet the dynamic needs of modern industrial processes.

Why Choose NxTek for a Shell and Tube Condenser Manufacturer in India?

Serves all the major segment :-

- Stainless Steel

- Carbon Steel

- Boiler Quality Carbon Steel

- Low Temperature Service Carbon Steel

- Plastics

- Material Testing

- Shell diameter: 4000 mm

- Shell thickness: 25 mm

- Overall length: 25 m

- Tubesheet thickness: 400mm

- Max Pressure: 200 kg/cm2

- Heat transfer area: 1 m2 to 4000 m2

- Max weight: 10 tonnes3