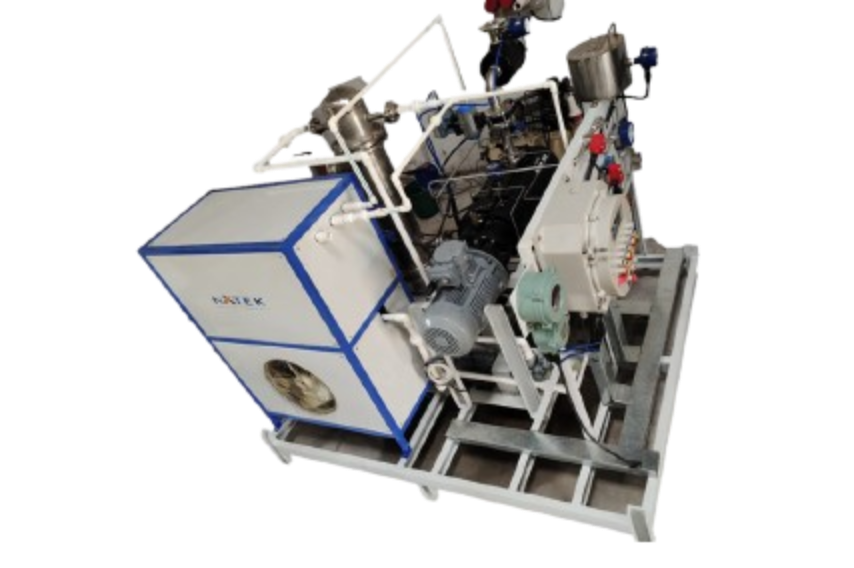

Dry Screw Vacuum Pumping System

Dry Screw Vacuum Pump System Manufacturer in India | NxTek

NXTEK Yantra Pvt Ltd is at the forefront of industrial innovation in India, delivering state-of-the-art solutions to meet the evolving needs of manufacturing. This advantages of NXTEK Yantra Dry Screw Vacuum Pump Systems, showcasing how these advanced systems redefine efficiency, reliability, and sustainability in various industrial sectors.

Why Choose Our Dry Screw Technology?

Manufactured by industry leaders at NXTEK Yantra, our dry screw vacuum pumps stand out with:

- Oil-Free Operation: No lubricants, minimizing contamination for a clean, dry vacuum.

- Innovative Design: Robust construction for durability and efficiency.

- Versatility: Handles diverse gases and vapors with ease. These advantages make them a top choice for manufacturers seeking sustainable and efficient solutions.

NXTEK: Innovative Dry Screw Vacuum Pump Systems for Enhanced Efficiency and Reliability

Innovative Dry Screw Technology

NXTEK Yantra's Dry Screw Vacuum Pump Systems incorporate innovative dry screw technology, eliminating the need for oil lubrication. This not only enhances operational cleanliness but also ensures a maintenance-free and environmentally friendly solution.

Optimized Performance Across Industries

Designed with versatility in mind, NXTEK Yantra's vacuum pump systems offer optimized performance across a spectrum of industries. From chemical processing to semiconductor manufacturing, these systems cater to diverse applications with precision and reliability.

Energy Efficiency and Cost Savings

One of the standout features of NXTEK Yantra's systems is their energy efficiency. By minimizing energy consumption, these vacuum pump systems contribute to significant cost savings over the long term, aligning with the industry's increasing focus on sustainability and operational cost reduction.

Compact Design for Space Optimization

The compact design of NXTEK Yantra's Dry Screw Vacuum Pump Systems allows for efficient space utilization in manufacturing facilities. This attribute is particularly valuable in industries where floor space is at a premium, enabling seamless integration into existing setups.

Reliable and Consistent Vacuum Levels

Precision is paramount in industrial processes, and NXTEK Yantra's systems excel in providing reliable and consistent vacuum levels. This reliability is crucial in applications such as vacuum distillation, packaging, and degassing.

Low Maintenance Requirements

The absence of oil lubrication in these vacuum pump systems translates to low maintenance requirements. This not only reduces downtime but also minimizes the environmental impact associated with traditional oil-lubricated systems.

Adherence to Industry Standards

NXTEK Yantra maintains a commitment to adhering to the highest industry standards. Its Dry Screw Vacuum Pump Systems comply with regulatory requirements, ensuring that clients operate within the framework of quality and safety benchmarks.

Remote Monitoring and Control Capabilities

NXTEK Yantra's systems are equipped with remote monitoring and control capabilities. This feature empowers operators to oversee and manage vacuum pump performance from a centralized location, enhancing operational efficiency.

Reduced Noise Levels

Noise pollution is a concern in many industrial settings. NXTEK Yantra's vacuum pump systems address this by incorporating design elements that result in reduced noise levels, creating a quieter and more conducive working environment.

Global Reach and Customer Satisfaction

With a global presence, NXTEK Yantra has earned a reputation for delivering excellence in vacuum pump technology. Positive feedback from satisfied clients underscores the reliability, efficiency, and longevity of these systems.

Continuous Innovation and Upgrades

NXTEK Yantra remains dedicated to continuous innovation. The company invests in research and development to ensure that its Dry Screw Vacuum Pump Systems evolve alongside industry advancements, offering clients access to cutting-edge technology.

Why Choose Us for Dry Screw Vacuum Pump System in India ?

NXTEK Yantra Pvt Ltd stands as a trailblazer in industrial technology, and its Dry Screw Vacuum Pump Systems exemplify a commitment to excellence. From innovative dry screw technology to energy efficiency, low maintenance requirements, and global customer satisfaction, these systems are poised to redefine standards in the world of vacuum pump solutions. As industries increasingly prioritize sustainability and operational efficiency, NXTEK Yantra’s offerings emerge as indispensable tools for driving progress and success in the manufacturing landscape.

Dry Screw Vacuum Pumping System

Key Feature's :-

- Customized MOC as per Process

- High Efficiency

- Vacuum upto 0.05 torr

- Oil Free Gas Path

- Low noice level & Vibration

- Long service Intervals

- Variable pitch, Screw, Mechanical Seal Design

System Specifications :-

- Vacuum Pump, Motor with Junction Box

Default Facility :-

- Control Panel

- Solvent Flushing

- N2Flushing & purging

- Actuated Isolation Valve

- Tempreture & Pressure Sensor